Types of concrete cracks – Plastic settlement cracking

|

What is Plastic Settlement Cracking?

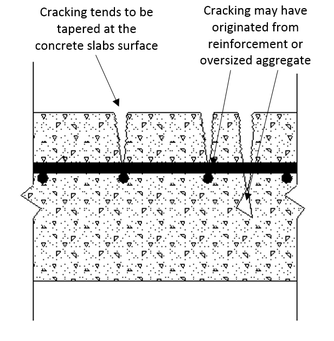

Plastic settlement cracks are so-called because they form while the concrete is still plastic i.e. it has not set. After it is placed in position, concrete undergoes a process known as ‘bleeding’. This process is a form of segregation where the water rises to the surface of the substrate, whilst the solids settle down. If there is no restraint during the placement of the concrete, such as reinforcing bar, then generally the slab settling will merely produce a slight lowering of the concrete surface. However, in a residential slab with reinforcing mesh for example, the effect of the settlement of the concrete slab over the restraint (the mesh) may produce a crack to form. This crack is identifiable as it generally follows the pattern of the reinforcing mesh. |

|

As the name suggests, the cause of plastic settlement cracking is the settlement of the solid particles whilst the concrete slab is curing.

The amount that a slab settles tends to be proportionate to the depth of the concrete i.e the deeper the concrete the greater the settlement. Due to this, cracking may also be identified at areas where concrete pours are greater in one particular area, such as beams. This is known as differential settlement.

How can plastic settlement cracking be avoided?

- A good quality concrete mix with lower bleeding characteristics will minimise the risk of plastic settlement cracking.

- A slump test should be undertaken to ensure the quality of the concrete mix prior to pouring. More cohesive mixes minimise the risk of bleeding.

- Increasing the cover of concrete to reinforcement mesh minimises the likelihood of cracks forming at the surface.

- When pouring footings, wetting the soil prior to the pour avoids excessive water loss from the base of the concrete.

- Ensuring that the formwork around the slab is rigid will avoid cracks forming as the formwork will not move during placement.

- Placing the concrete in deep sections first, such as beams, reduces the likelihood of differential settlement. Care should be taken when adopting this practice however, as the development of ‘cold joints’ may occur. As a general rule, no longer than 45 minutes should elapse before placing fresh concrete against concrete previously placed, although this is obviously dependent upon conditions such as the site and weather conditions.

- The concrete should be fully compacted, vibrated and cured.

How is plastic settlement cracking assessed when a building inspection is carried out?

Cracking should be clearly identified and assessed by a trained and appropriately qualified building inspector. All cracking should be classified in accordance with AS 2870, and advice should be given accordingly. In instances where the impaired cracking is deemed not defective, a qualified building inspector may still recommend the affected area be remedied at the expense of the builder.

For example, as plastic settlement cracking may expose areas of the slab reinforcement mesh, the probability of concrete cancer is greatly increased. Also, as the creation of a void underneath the reinforcement mesh is also associated with plastic settlement cracking, any subsequent drying shrinkage may result in cracking through the full depth of the concrete member. The cost of the builder rectifying the crack in the first instance would therefore be insignificant in comparison to allowing the crack to potentially develop.