Do I need a lintel? A guide to lintel installation

What is a lintel?

- Galvanised or stainless steel

- Reinforced or prestressed concrete

- Reinforced or prestressed masonry stone

Do I need a lintel?

How are lintels installed?

When installing a lintel it is important to adhere to the following good practices:

- Be careful not to chip the lintels coating – Corrosion protection is an essential component in ensuring that the lintel installed does not cause structural damage in the future. Moisture needs only the smallest of exposed area to penetrate, creating areas of rust and causing the lintel to expand.

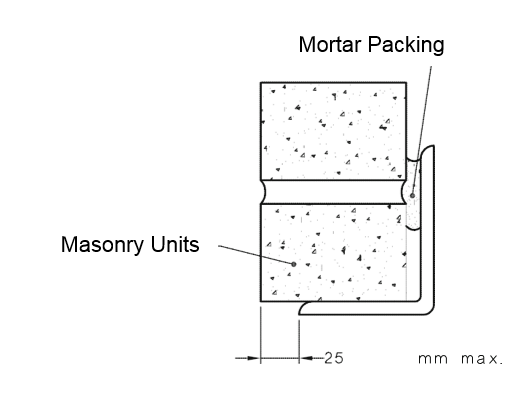

- The vertical leg of a steel lintel should always be the highest – Careful calculations are made off-site to ensure that the lintel provided is adequate to support the load above it. If the lintel is incorrectly installed, the lintel may no longer be able to support the load and may visibly deflect over time, causing loads to be place upon frames.

|

|

Will my building inspector check that lintels are adequately installed?

Unfortunately at practical completion it is not possible to check all of the items above, as a building inspector will be unable to look down the cavity once the roof cover has been installed. Additionally, lintels are also required internally over certain openings, which will be unable to be assessed if all of your internal walls have already been plastered.

We have witnessed lintel non-compliance both internally and externally, so it is important to consider inspections at every stage of the building process. To view our building inspection prices as well as the savings that you can make by combining inspections, please visit our building inspection prices page.