Roof frames may be constructed from steel or timber, and are generally constructed as a coupled roof framework or truss frame construction. There are differing pros & cons to each method of construction, although this guide will focus of the possible defects associated with the two forms of construction.

What is a coupled roof Framework?

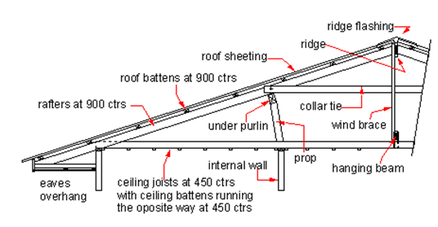

A coupled roof is pitched roof construction with a roof slope of not less less than 10 degrees, with ceiling joists and collar ties fixed to opposing common rafter pairs and a ridgeboard at the apex of the roof.

What are some common defects associated with coupled roof construction?

The following defects may be associated with the construction of a coupled roof:

- Ceiling Joists no longer located on wall: When renovations are undertaken internally, care must be taken when assessing the demolition of internal walls. Even if the walls are not load-bearing (that is, no struts/props or beams rest on top of them), ceiling joists may still require the wall for support. This may cause the ceiling to sag, and in time, collapse.

- Struts found to be directly on the ceiling frame: If struts are found to be directly onto the ceiling frame, no transfer of load to the foundations exists, and the struts may cause major structural damage as they will be unable to support the load applied to the roof.

- Strutting beams have been installed hard against the ceiling line: Strutting beams should be raised above ceiling, as ceiling will sag in this location, due to the weight of the roof load. Blocking should be provided between strutting beams and wall plates to provide an initial clearance of 25 mm at mid-span. This clearance is between the underside of the beams and the tops of ceiling joists, ceiling lining or ceiling battens, as appropriate.

- Strutting beam has been used as a hanging beam: Strutting beams should not double as hanging beams. This is because they are likely to sag and will cause the ceilings to sag. Also, they transfer roof loads that are often dynamic because of wind pressure acting on the roof. This means they may move up and down or from side to side, causing the ceiling to move and possibly crack.

- Strut Collapse: If a strut has collapsed then no support is offered to the under purlins and ultimately collapse will occur.

Under purlin has visible signs of deflection: Usually due to poor strut spacing, under purlins may show signs of deflection due to the load placed upon them. Additionally strutting may be required or remedial works in the form of a bracing system may be implemented. - Rafters have visible signs of deflection: This may be due to inadequate support from the under purlins when a load is placed upon the roof structure.

- Rafters have visible gaps at the bottom of their connection to the ridge: This may be due to poor workmanship when fixing, or may be a sign of the roof ‘spreading’. Always monitor should gaps appear and seek the advice of a suitably qualified person

What is a truss frame construction?

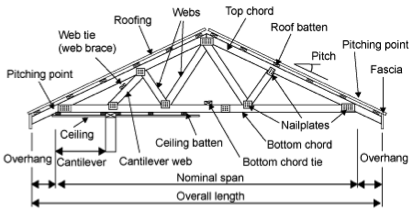

A truss frame system is an engineered roof frame system designed to carry the roof or roof and ceiling, usually without the support of internal walls.

What are some common defects associated with truss roof construction?

As truss systems are manufactured off site, generally defects are only associated with modification of the trusses after erection or under engineering in supporting loads (or if additional unforeseen loads are placed upon the roof). These defects are described in detail below.

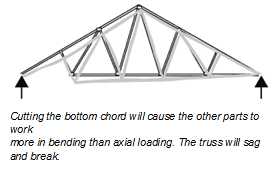

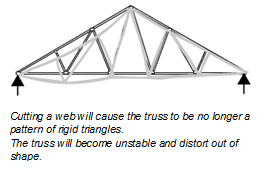

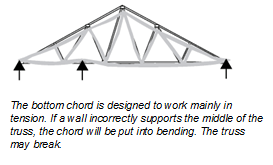

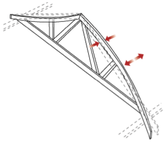

Truss modification: Any truss system that has been cut or modified may sacrifice the structural integrity of the roof. The following diagrams depict how these modifications may affect the structural integrity of the roof.

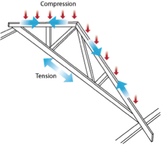

Deflection of truss: Trusses need to be prevented from buckling because this causes them to move outside their plane of strength (ie plane of vertical strength). Fixing roof battens to the top chords at regular intervals restrains the sideways movement in the top chords. Battens should be fixed to every truss.

Note that the identification of deflection should always be on the underside of the truss. During production, trusses improve on traditional rafter design by forcing an upward bend into the chords of trusses. This is referred to as a ‘camber’.

A camber helps to resist loads. For example, the amount of bend is calculated to help resist the load of tiles and ceiling lining. The calculations are designed to ensure the truss eventually flattens out to provide straight chords once it is fully loaded